Mortise and Tenon Joinery

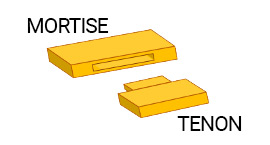

There are 3 types of mortise and tenon joinery that we use at Meridian Products in our product construction. We use the blind mortise and tenon joint, the notched mortise and tenon joint (aka haunched), and the coped mortise and tenon joint. Mortise and tenon joints are an extremely old construction technique that can be traced back thousands of years and is considered one of the strongest joints next to the dovetail joint. The mortise is the hole that is cut into a board and the tenon or tongue is the piece that is shaped to fit into the mortise. Think of it as square peg going into a square hole.

There are 3 types of mortise and tenon joinery that we use at Meridian Products in our product construction. We use the blind mortise and tenon joint, the notched mortise and tenon joint (aka haunched), and the coped mortise and tenon joint. Mortise and tenon joints are an extremely old construction technique that can be traced back thousands of years and is considered one of the strongest joints next to the dovetail joint. The mortise is the hole that is cut into a board and the tenon or tongue is the piece that is shaped to fit into the mortise. Think of it as square peg going into a square hole.

The Blind Mortise and Tenon Joint:

This joint has the strength of a mortise and tenon joint but on the surface, it gives an appearance of a butt joint. The blind mortise and tenon joints have a mortise that does not extend completely through the stile. Therefore, once the pieces are assembled the tenon is not visible but rather hidden in the construction. We use the blind mortise and tenon construction in our face frames, similar to the picture shown above.

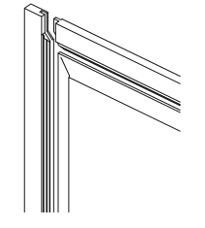

The Notched Mortise and Tenon Joint (Haunched):

Notched mortise and tenon joints have a very short tongue that extends from the shoulder of the rail and is located between the rails edge and the tongue’s edge. This mortise and tenon joints were created to fill the void that other mortise and tenon joints would leave in construction. When a door was constructed with a frame and panel there would be a visible groove or void at the end of the slot. In order to get rid of this groove a new design needed to be created, the notched or haunched joint. This new design fills this groove and gives the door a better-looking construction with added strength. Depending on how the piece is being used the rail can have a notch on only one side or both sides.

Notched mortise and tenon joints have a very short tongue that extends from the shoulder of the rail and is located between the rails edge and the tongue’s edge. This mortise and tenon joints were created to fill the void that other mortise and tenon joints would leave in construction. When a door was constructed with a frame and panel there would be a visible groove or void at the end of the slot. In order to get rid of this groove a new design needed to be created, the notched or haunched joint. This new design fills this groove and gives the door a better-looking construction with added strength. Depending on how the piece is being used the rail can have a notch on only one side or both sides.

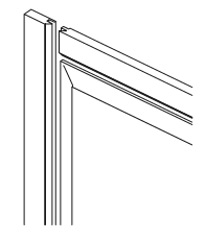

The Coped Mortise and Tenon Joint:

The coped mortise and tenon joints are a type of construction where all the frame members are given a molded profile on the inside edge that will be jointed to the panel. Dictionary.com gives the following definition, to join (two molded wooden members) by undercutting the end of one of them to the profile of the other so that the joint produced resembles a miter joint (90o angle). This angle will be shown on each of the 4 corners. The result of this joint is a much more elegant design. The tight-fitting durability gives this joint an advantage is its strength. Which is why this design is used in more intricate pieces like glass doors and glass doors that exhibit patterns. This joint takes an advanced carpentry skill which is why these types of projects are more expensive than other joineries.

The coped mortise and tenon joints are a type of construction where all the frame members are given a molded profile on the inside edge that will be jointed to the panel. Dictionary.com gives the following definition, to join (two molded wooden members) by undercutting the end of one of them to the profile of the other so that the joint produced resembles a miter joint (90o angle). This angle will be shown on each of the 4 corners. The result of this joint is a much more elegant design. The tight-fitting durability gives this joint an advantage is its strength. Which is why this design is used in more intricate pieces like glass doors and glass doors that exhibit patterns. This joint takes an advanced carpentry skill which is why these types of projects are more expensive than other joineries.