Want Quality Results? Avoid These 6 Common Orbital Sander Mistakes

Wood preparation lays the groundwork for exceptional finishing, and proper sanding is crucial for achieving the best results.

While orbital sanders are relatively straightforward to use, subtle user mistakes can sabotage even the highest-quality materials. And these errors often don’t reveal themselves until you apply your finish.

Avoid these 6 common mistakes to take your craftsmanship to the next level and ensure your cabinetry components attain the smooth, even surface they deserve!

1. Applying Excessive Pressure

Pressing down too hard on your sander is a common mistake.

It can be tempting to apply more pressure to speed up the process, but this can create swirl marks, cut-through, and uneven sanding. Excessive pressure also generates heat that causes premature loading of your abrasive discs.

The fix: Let gravity and the weight of your sander do the work. Each grit is designed to remove a certain amount of material. If you need to remove more, use a coarser grit instead of pressing harder. The sander should always glide smoothly across the surface with minimal downward force from your hands.

2. Moving Too Fast or Too Slow

For consistent results, watch your speed control.

Moving the sander too fast leads to missed spots and inadequate material removal, and lingering too long in one area creates depressions and over-sanding.

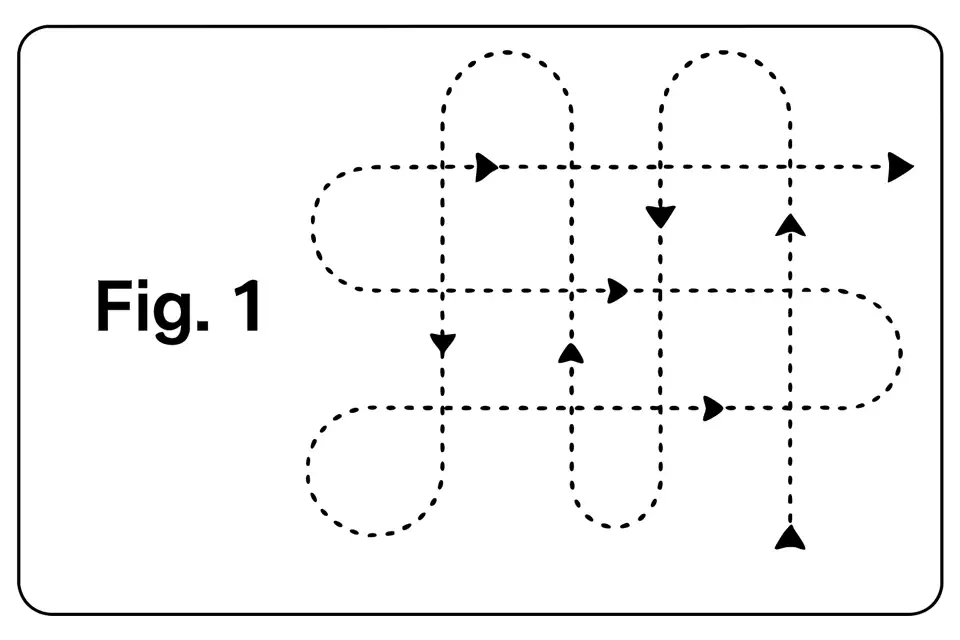

The fix: Maintain a steady, deliberate pace. One helpful tip – sand straight up the grain from bottom to top. Then, do another strip but overlap about 50% of the strip you just sanded. This technique helps to consistently create even coverage.

3. Incorrect Speed Settings

Your sander’s RPM settings will definitely impact finish quality.

For pneumatic sanders, maintain 90 PSI at the machine and keep units well-lubricated. For most woodworking applications, electric sanders typically perform best in the 10,000 RPM range.

The fix: Set pneumatic sanders to their highest speed setting to avoid swirl marks, unless working on special applications that require slower speeds. For electric sanders, follow the manufacturer’s recommended speeds for your particular application.

4. Poor Starting and Stopping Technique

Starting the sander in the air or stopping it while still on your work surface will create distinct swirl marks.

When you start the sander while it’s already in contact with the wood, it struggles to achieve proper contact. Similarly, allowing the sander to stop while touching the workpiece creates uneven results as it slows down.

The fix: Remember this rule – “Start on, Stop off.” Always place the sander on the surface before turning it on, and lift it off the surface before turning it off. This simple technique will help you eliminate start and stop swirl marks entirely.

5. Tilting the Sander

Using the sander at an angle to address problem areas will create more issues than it solves. The technique creates uneven surfaces, destroys abrasive discs, and damages the backup pad.

The fix: Keep the sander flat against the surface at all times. One helpful tip – only allow 20% of the pad edge to go over the end of the surface. This reduces the risk of any rounding. If you encounter surface irregularities, switch to a coarser grit and sand the entire surface, or use an appropriate filler product before sanding.

6. Neglecting Abrasive Disc Maintenance

Using worn or damaged sanding discs creates dips, missed spots, and inconsistent finishes. In addition, misaligned disc holes reduce dust extraction efficiency which can lead to a damaged workpiece.

The fix: Replace sanding discs every 15-30 minutes during heavy use. Also invest in quality brands that provide longer-lasting performance. And for optimal dust extraction, always align the holes in your sanding disc with the pad holes.

Incoming: Exceptional Results!

Remember that exceptional cabinetry begins with exceptional preparation.

Mastering these 6 orbital sanding fundamentals will take your techniques from adequate to exceptional, and set the stage for true beauty in your cabinetry components.

Have a finishing question about one of your projects? Connect with our team of experts today!