Wood and How it Cuts

By Katie Van Blargan, Meridian Customer ServiceWhat draws your attention most when you are looking at an unfinished wood product? The natural beauty, the color, its characteristics? It’s truly astounding how each mark is unique to the tree that it came from. What you may not realize is that some of these natural marks are actually generated in the way the wood is cut.

Meridian Products uses three main types of cuts: plain, rift, and quarter cut. Let’s dive a little deeper on these cuts and review the benefits each provides.

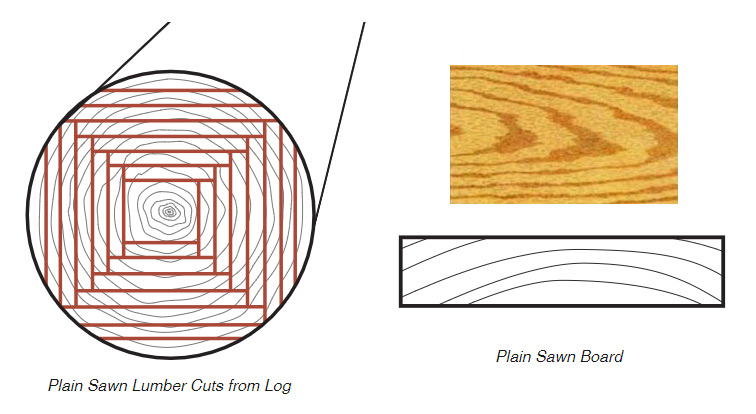

Plain Sawn Lumber Cuts

Plain sawn, as shown above, is commonly known as flat sawn lumber. Because it can be produced quickly, this cut is readily available and very cost effective, making it the most popular. It is available on all of our wood types and is typically cut so the annular rings are 30 degrees or less to the face of the board. This cut provides you with an efficient and well done cut!

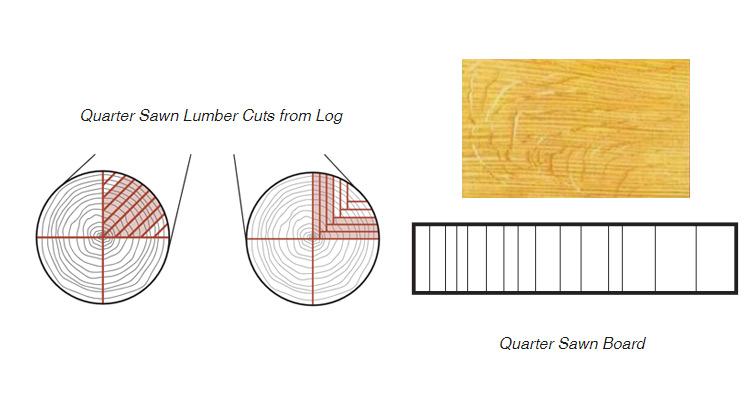

Quarter Sawn Lumber Cuts

Next let’s dive into a beautiful cut that features natural “beauty marks.” The quarter sawn cut is often seen in your oak wood products. This cut is harder to produce because it is cut at a 60 to 90-degree angle to the annular rings – to the face of the board. The goal of this cut is to provide a cut that is as close to perpendicular to the face as possible. It provides a straight grain appearance with natural “flecking” (which resembles tiger stripes) in the wood. This cut is naturally beautiful and stronger than the plain sawn cut.

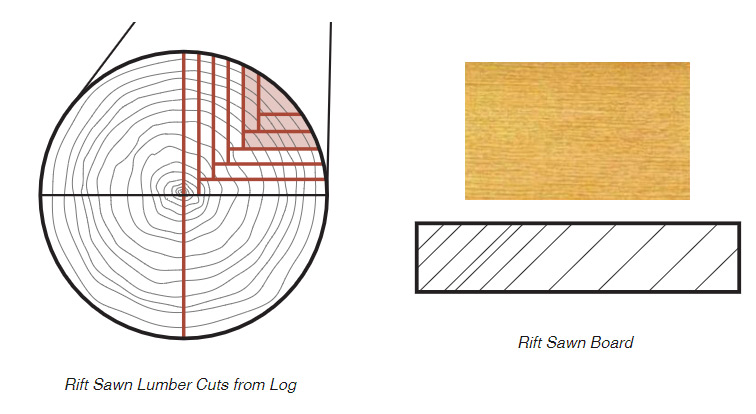

Rift Sawn Lumber Cut

The last cut that we do at Meridian Products is the rift-cut. Just like quarter sawn, this cut is most commonly seen in the oak species. The rift cut tends to be the most-costly cut due to the amount of material that is lost in the process. It’s done on a 45- degree angle to the annular rings to the face. Rift cutting limits flecking, in turn producing a final product that has a straight grain with no natural blemishes – creating a beauty of its own.

Just like the multiple species that can be used to build a dream kitchen, there are multiple cuts to consider as well. Each cut is unique in its own way. Introduce these cuts to your customer and showcase the beauty of the pieces that will go into their dream project!